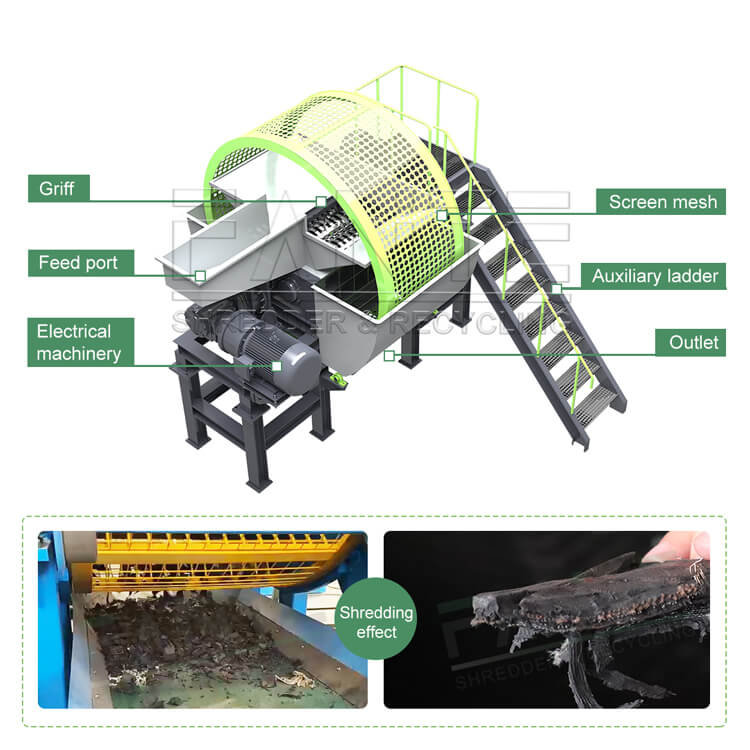

What Is a Tire Shredder?

A tire shredder is a machine specifically designed to shred and break down used tires into smaller, manageable pieces. This process is crucial for recycling, as it prepares tires for further processing into materials like crumb rubber, rubber mulch, and other products. These machines come in various sizes and models, capable of handling all types of tires—from passenger car tires to large truck and industrial tires.

How Tire Shredders Work

Tire shredders use powerful cutting blades to slice through the tough, rubbery material of tires. The machine typically works in stages:

Primary Shredding

In the initial stage, the shredder tears tires into rough chunks or strips. This step prepares the material for more precise processing.

Secondary Shredding

During this stage, the shredded tire pieces are further reduced in size. Depending on the specific model and configuration of the tire shredder, the output can range from larger rubber chunks to fine rubber granules.

Separation of Materials

Tire shredders often feature advanced separation technology, removing materials like steel wire and fibers embedded in tires, ensuring a clean output for reuse.

Key Benefits of Using a Tire Shredder

Using a tire shredder in your recycling operation offers numerous advantages, not only improving efficiency but also benefiting the environment and reducing operational costs.

1. Environmentally Friendly

Discarded tires take decades to decompose, and when burned, they release harmful pollutants. By using a tire shredder, you actively reduce landfill waste and contribute to a cleaner environment. The shredded tire materials can be repurposed into a variety of products, reducing the need for virgin raw materials.

2. Cost-Effective

Tire shredders help reduce the volume of waste, lowering transportation and disposal costs. Once tires are shredded, the material can be sold for a profit, whether it’s used in construction, road surfacing, playground surfaces, or other applications.

3. Increased Efficiency

A tire shredder makes the recycling process significantly more efficient. Without this machinery, breaking down tires manually would be labor-intensive and time-consuming. Tire shredders can handle large volumes of tires quickly and consistently, boosting productivity.

4. Maximized Resource Recovery

By using a tire shredder, you’re able to recover valuable materials like rubber, steel, and textiles from tires. These materials can then be sold or reused in new products, creating additional revenue streams for your business.

5. Versatility

Tire shredders can handle various types of tires, including those from cars, trucks, buses, and even industrial equipment. This flexibility makes them an invaluable asset for recycling facilities of any size or focus.

Tire Shredder Applications

Shredded tires are in demand across numerous industries, contributing to a growing market for recycled tire products. Some common uses include:

- Rubber Mulch:Shredded tires can be repurposed as rubber mulch for landscaping and playground surfaces, offering a durable and safe alternative to traditional mulch.

- Crumb Rubber:This fine rubber material is often used in athletic tracks, artificial turf, and molded rubber products.

- Alternative Fuels:Shredded tires can be used as Tire-Derived Fuel (TDF) in industries like cement production, where they burn cleaner than coal.

- Road Construction:Shredded rubber is also incorporated into road surfaces, making them more durable and resistant to cracking.

Why a Tire Shredder Is a Smart Investment

Investing in a tire shredder is a long-term strategy for companies looking to stay ahead in the tire recycling industry. Whether you’re a small recycling operation or a large industrial facility, a tire shredder enhances your processing capabilities and allows you to scale your business efficiently.

How to Choose the Right Tire Shredder

Choosing the right tire shredder for your business depends on several factors:

- Capacity:Consider the volume of tires you need to process. Larger facilities will benefit from heavy-duty shredders capable of processing thousands of tires per hour, while smaller operations may only need a mid-sized machine.

- Output Size:Determine the size of shredded materials you require. Some shredders offer multiple stages to produce finer granules, while others may only shred tires into larger chunks.

- Customization Options:Some manufacturers offer customizable shredding solutions to meet specific industry needs. This can include varying blade sizes, motor power, and additional features for separating materials.

Conclusion: Work Smarter with Tire Shredders

In the tire recycling industry, efficiency is everything. A tire shredder allows you to process waste faster, reduce costs, and generate valuable byproducts for resale. By investing in a high-quality tire shredder, your company can work smarter, not harder, while playing a pivotal role in reducing global tire waste.

If you’re looking to integrate a tire shredder into your recycling operation or want to learn more about how it can benefit your business, feel free to contact us. Our team of experts is ready to assist you with tailored solutions that meet your needs.