Tire Shredder Machine

Tire Shredder

Product model: FTHS-T

Type: Double Shaft Shredder

Material: Provide customized services and a variety of materials to choose from

Color: Customized service available

Brand: Fante

Tire Shredder Machine

The tire shredder efficiently pre-shreds waste tires in tire recycling lines. In addition, a built-in sieve screens tire fragments into the appropriate size for the next processing stage, ensuring smooth downstream operations. Moreover, the shredder handles various types of waste tires—including car tires, truck tires, and OTR tires—and offers customization options to meet specific material types and capacity requirements.

Furthermore, the tire shredding machine features premium materials that ensure superior durability. Its fully welded, high-quality steel body and imported high-strength alloy steel blade shaft provide excellent wear resistance and a long service life, making it a reliable choice for demanding recycling environments.

Feature Overview

- High-Efficiency Tire Shredding – Stable processing of passenger, truck, and OTR tires with high throughput.

- Precise Output Size Control – Interchangeable screens ensure precise and consistent rubber chip size.

- Intelligent PLC Control System – Automated PLC system for easy operation and reliable performance.

- Advanced Safety Protection – Overload and jam protection with automatic stop and reverse.

Shredding Effect

As the circular economy gains momentum and reshapes the way we view resources, the machine has become an integral part of this change. With its cutting-edge technology and high operational efficiency, it paves the way for new solutions in waste tire management.

The machine process begins with the introduction of scrap tires. These tires, whether from cars, trucks, or motorcycles, have a new destiny at this moment. The operation of the machinery begins. Tire Shredding machine converts waste tires into reusable pellets with its efficient and precise shredding technology.

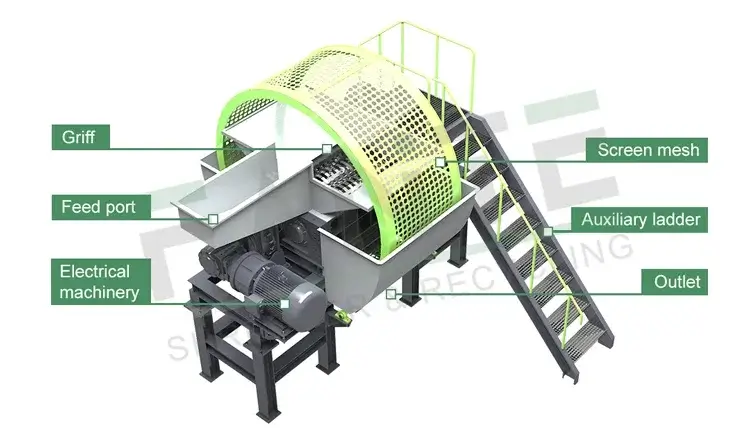

Structure design

Product parameters

| Model | FTHS-T-800 | FTHS-T-1000 | FTHS-1200 | FTHS-T-1300 |

| Cutting Chamber L*W(mm) | 804*680 | 1004*680 |

1204*920

|

1304*920 |

| Equipment Weight(kg) |

5700

|

7000

|

16500

|

18500

|

| Blade Diameter (mm) | 450 | |||

| Final Product(mm) | 50 | |||

Product actual pictures