Large Copper Wire Granulator

Product model: FTG

Type: Copper Wire Granulator

Material: Provide customized services, a variety of materials to choose from

Color: Customized service available

Brand: Fante

Large Copper Wire Granulator

Copper wire pelletizer is an innovative and essential piece of equipment in the field of metal recycling. These machines play a vital role in converting scrap copper wires into valuable resources, making them highly sought after across various industries. Copper wire pelletizers are designed to efficiently process and recycle all types of copper wires and cables, regardless of their condition. It can handle everything from small and thin wires to large and thick cables. The granulation process involves stripping the insulation off the copper wire and then reducing the copper into granules or small particles.

Product Details

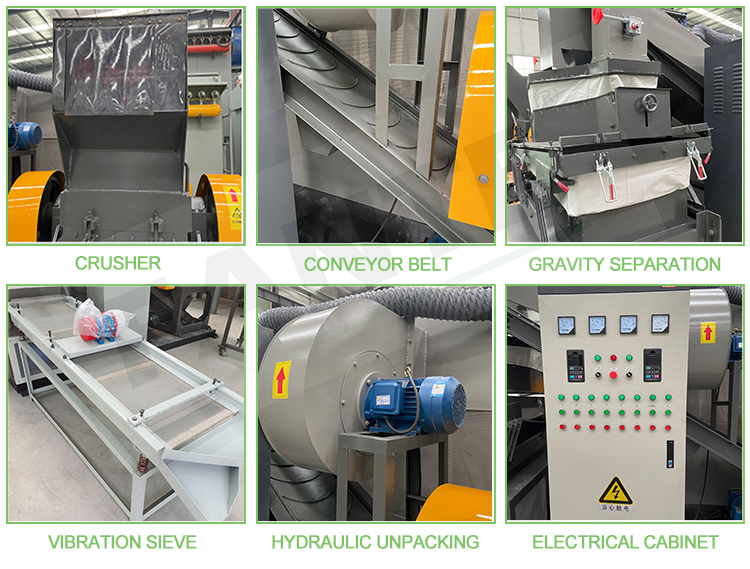

The copper wire granulator offers precision processing for scrap copper wire, ensuring high efficiency and recovery rates. These machines feature several key components designed to optimize performance and maximize copper recovery:

- Feeding system: Granulators typically have robust feeding systems that accept various types and sizes of copper cables. The machine handles both insulated and non-insulated wires, offering high versatility for a wide range of recycling applications.

- Cutting mechanism: Inside the granulator, a powerful cutting mechanism cuts the copper wire into smaller pieces. This process is essential to prepare the wire for further granulation.

- Pelletizing Chamber: Once the wires are cut into smaller pieces, they enter the pelletizing chamber. Here, sharp blades further crush the material into copper particles or fine particles. Operators can adjust the particle size to meet specific processing requirements.

Shredding Effect

Product Parameters

| Model | FTG-600 | FTG-800 | FTG-1000 |

| Total Power | 42.19kW | 67.24kW | 105kW |

| Output | 400-700kg | 600-800kg | 700-1000kg |

| Applicable | 0.1-30mm cable | ||

| Equipped with a double-shaft shredder, the maximum wire processing diameter can reach 50mm | |||

| Weight (kg) | 3450kg | 6200kg | 10000kg |

| Application | The cable copper sheath and sheath should be worn separately | ||

| Aspect | 3700*1900*2200mm | 7600*6800*2200mm | 10000*7000*2800mm |

Product actual pictures