In today’s competitive recycling industry, maximizing output and metal purity is crucial. A high-capacity copper wire granulator offers the perfect solution for large-scale scrap processing operations. But how do you know if it’s the right fit for your business? In this article, we’ll explore the benefits, working process, and key considerations of investing in a professional-grade copper wire recycling machine.

Why Choose a High-Capacity Copper Wire Recycling Machine?

If your facility deals with large volumes of waste cables—such as industrial cables, household wiring, or automotive wire harnesses—you need a robust solution that combines speed, durability, and recovery efficiency. A copper wire recycling machine with high processing capacity can:

- Process 500–1000 kg/hour of waste wire materials

- Recover up to 99.9% pure copper with advanced separation technology

- Minimize labor through automated operation and continuous feed systems

- Support ROI growth by turning scrap into valuable copper granules

Whether you’re expanding your facility or upgrading your current setup, a copper wire granulator designed for heavy-duty use is a smart long-term investment.

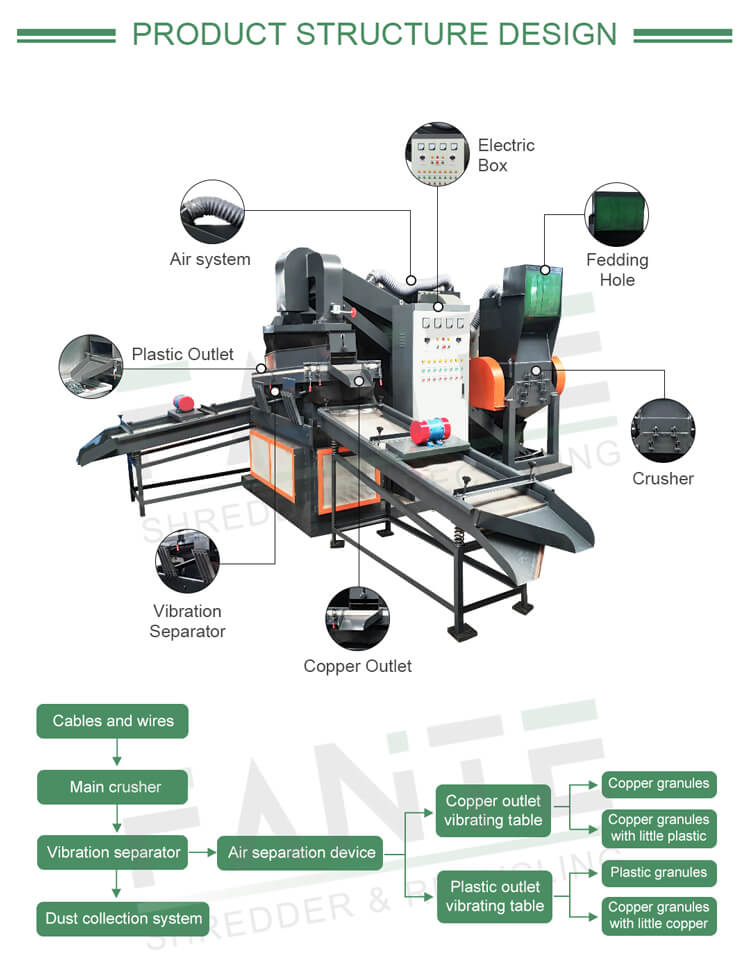

How Does a Copper Wire Granulator Work?

The copper wire recycling process involves multiple stages to ensure efficient separation of copper and plastic without chemical or water use:

1. Shredding

The machine shreds the waste cables into smaller pieces for easier processing.

2. Granulation

Copper and plastic are further reduced into fine particles, ideal for separation.

3. Air Separation

An integrated air separation system efficiently separates the copper granules from the plastic insulation.

4. Collection

Clean copper is collected for resale or reuse, while the plastic can also be recycled or repurposed.

This dry-type recycling method is eco-friendly, easy to operate, and ideal for businesses aiming for sustainable operations.

What to Consider Before Buying a Copper Wire Recycling Machine

When choosing the right copper wire granulator, focus on:

- Processing capacity that meets your daily output

- Purity rate of copper recovery

- Type of wires supported (e.g., fine wires, mixed cables, armored cables)

- Power consumption and space requirements

- Manufacturer support (installation, training, spare parts)

A well-designed copper wire recycling machine reduces downtime, ensures consistent output, and helps you meet environmental regulations.

Conclusion: Upgrade to a Smarter Copper Wire Recycling Solution

If you’re dealing with large volumes of scrap cable, a high-capacity copper wire granulator can transform your operations. With the right setup, you’ll not only boost productivity but also recover high-value copper with minimal waste.

Looking for a copper wire recycling solution that delivers performance, efficiency, and durability? Contact us today to get a tailored quote and machine recommendation.