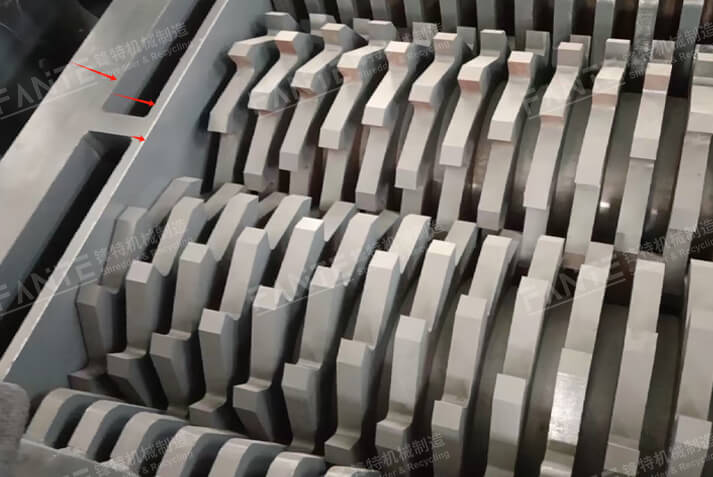

The shredder knife box is one of the most critical components of a shredder. It houses the cutting blades and supports the entire shredding process. When selecting a double shaft shredder, many customers focus on the knife box sidewall thickness. A common question is: Is a thicker sidewall always better?

In this article, we will analyze the impact of knife box thickness, explore different materials used in shredder knife boxes, and help you determine the optimal design for durability and efficiency.

The Importance of Shredder Knife Box Sidewall Thickness

The sidewall thickness of the shredder knife box plays a key role in determining the machine’s overall performance and lifespan. The main considerations include:

- Durability: A thicker shredder knife box can withstand high-pressure shredding without deformation.

- Longevity: Thicker sidewalls reduce wear and tear, extending the lifespan of the machine.

- Structural Integrity: A double-shaft shredder generates strong forces during operation. If the sidewall is too thin, it may bend over time, leading to reduced efficiency and maintenance issues.

1. Comparison of Knife Box Materials

The shredder knife box can be made from different materials, primarily Q235B and Q345B:

| Material | Description | Strength | Durability |

| Q235B | Standard carbon steel (iron) | Moderate | Less durable, may deform over time |

| Q345B | High-strength alloy steel | High | More durable, longer lifespan |

- Q235B (Iron): A common material used in shredder knife boxes, offering moderate strength but prone to bending over time, especially when processing hard materials.

- Q345B (Alloy Steel): A stronger material with higher resistance to wear and deformation, making it ideal for heavy-duty double shaft shredders.

2. Why a Thicker Knife Box Sidewall is Better

A thicker shredder knife box sidewall provides significant advantages:

- Prevents Deformation: Thin sidewalls can develop a curvature over time due to the continuous impact of shredding forces.

- Enhances Stability: A sturdy double-shaft shredder requires a robust structure to ensure smooth operation without vibrations.

- Increases Service Life: Thicker sidewalls improve the overall durability of the shredder, reducing maintenance costs and downtime.

3. Finding the Optimal Thickness

While thicker sidewalls offer durability, excessive thickness can increase weight and cost. The optimal thickness depends on:

| Blade Diameter | Φ400 | Φ450 | Φ500 | Φ600 | Φ650 | Φ700 | Φ800 | |||||||

| Side Wall tickness | 100+25+60 | 120+25+100 | 140+35+125 | 160+45+115 | ||||||||||

| Wall Panel Material | Q345B | |||||||||||||

| Spindle Diameter | Φ190 | Φ220 | Φ260 | Φ320 | Φ340 | Φ430 | ||||||||

- Material Hardness: For soft materials (plastics, paper), a moderate sidewall thickness is sufficient.

- Shredding Intensity: For metals, rubber, and industrial waste, a thicker shredder knife box is recommended.

- Machine Design: The structure of the double-shaft shredder should balance strength and efficiency to ensure smooth operation.

Conclusion

When selecting a shredder , the knife box sidewall thickness is a crucial factor. Thicker sidewalls provide better durability, stability, and a longer lifespan. However, the choice should also consider the material used—Q345B alloy steel is generally superior to Q235B iron for heavy-duty applications.

For industries that require high-performance double-shaft shredders, investing in a sturdy shredder knife box with a proper thickness ensures long-term efficiency and lower maintenance costs.