As technology rapidly evolves, so does the volume of discarded electronics. From smartphones to servers, e-waste is one of the fastest-growing waste streams in the world. Efficient e-waste recycling not only protects the environment but also recovers valuable materials like copper, gold, and aluminum. In this article, we’ll explore the machines that make e-waste recycling possible and effective.

The Importance of E-Waste Recycling

Why E-Waste Management Matters

Electronic waste often contains toxic substances like lead, mercury, and cadmium. If improperly handled, these materials can leach into soil and water, posing serious environmental and health risks. By using a modern e-waste recycling machine, recyclers can safely extract reusable resources while minimizing ecological damage.

Global Demand for E-Waste Recycling Solutions

With stricter regulations on waste management and a growing need for sustainability, countries and companies alike are investing heavily in e-waste infrastructure. This demand has led to the development of high-efficiency systems like the e-waste shredder and e-waste crusher machine.

Key Equipment in E-Waste Recycling

E Waste Recycling Machine: Complete Recovery System

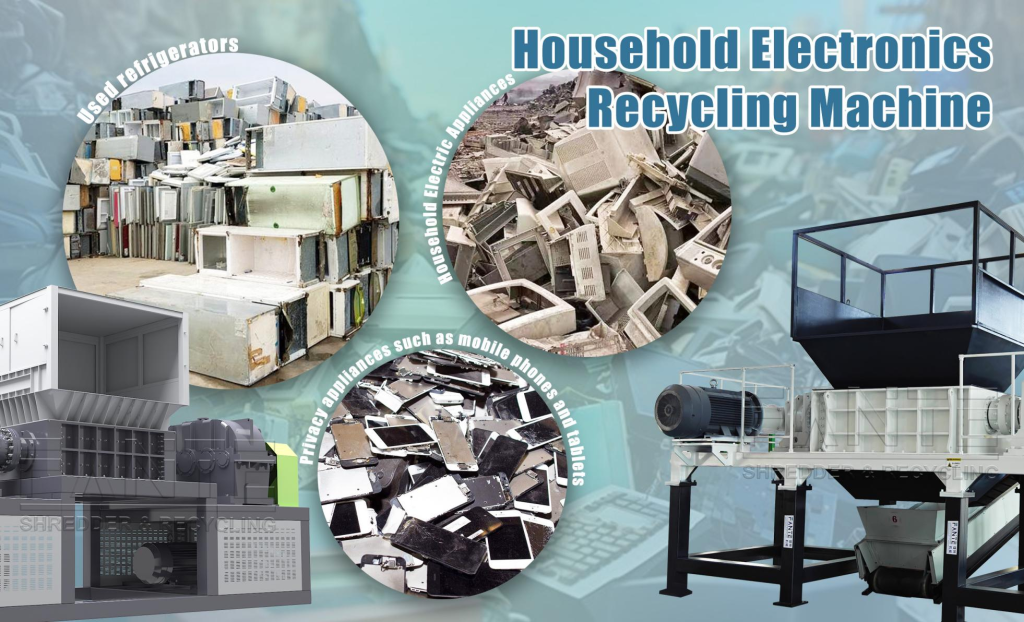

The machine integrates multiple stages of processing—from shredding to separation. These machines are designed to handle a wide variety of electronics including circuit boards, cables, and small appliances. They often include sorting, metal separation, and dust collection systems for a complete, clean recycling solution.

E Waste Shredder: The First Step in E-Waste Processing

The e waste shredder is a heavy-duty industrial shredder used to reduce bulky electronic waste into smaller, manageable pieces. It’s the essential first step in the recycling line. By breaking down the material, it prepares the waste for further refinement in downstream equipment.

E Waste Crusher Machine: Precision Grinding for Separation

Once the material is shredded, it is passed into an e waste crusher machine, which further pulverizes the waste into fine particles. This is critical for separating metals from non-metals, enabling high recovery rates for valuable resources.

Benefits of Using Modern E-Waste Recycling Machines

| Feature | Benefit |

|---|---|

| High metal recovery rate | Maximizes profit from precious metals |

| Environmentally friendly | Minimizes emissions and toxic leaks |

| Modular system design | Easy to scale according to plant size |

| Automated processing | Reduces labor and increases efficiency |

Equipping your facility with a reliable recycling machine, supported by an efficient shredder and crusher machine, significantly enhances recycling productivity and ROI.

Conclusion

E-waste is both a challenge and an opportunity. By investing in advanced recycling technology, such as machines, companies can take part in a circular economy while contributing to global sustainability. Tools like the shredder and crusher machine are the foundation of any efficient recycling line, ensuring cleaner processes and higher material recovery.

Looking for the right solution for your e-waste processing needs?

Contact us today to learn more about our high-performance e-waste equipment and customized system design.