MATERIAL

The Smarter Way to Recycle Plastics

The widespread use of plastic in industrial mass production is largely due to its exceptional versatility. However, the resultant surge in plastic waste calls for efficient plastic recycling methods. Plastic recycling machine convert plastic waste into pellets that can be reused for material recovery or energy utilization.

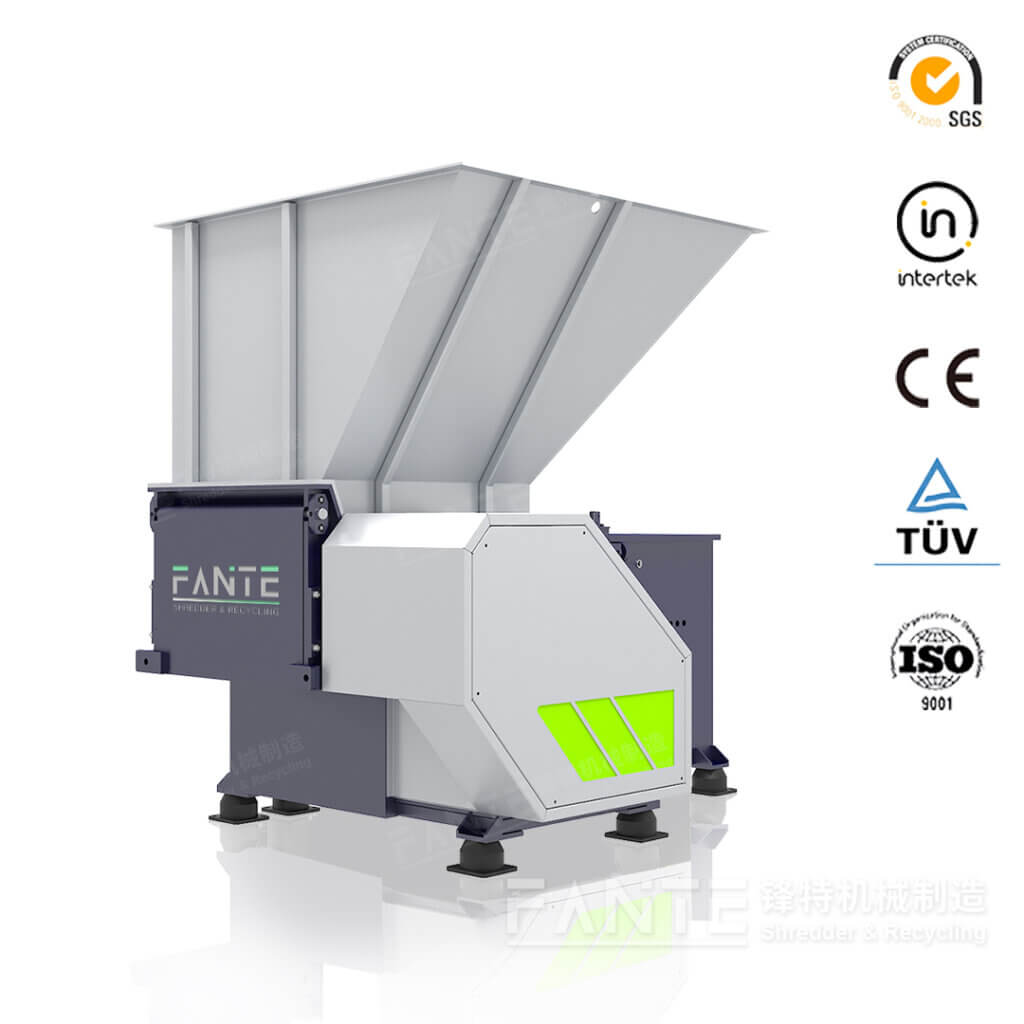

To address this environmental challenge, Fante plastic shredders have been specifically engineered to optimize the complex recycling process. Our shredders are designed to efficiently manage a wide range of plastic waste, ensuring a sustainable and cost-effective solution in the dynamic world of industrial production. By integrating advanced shredding technology, we contribute to a more sustainable future through effective waste management and material repurposing.

Bottle

Film

Barrel

Tray

Block

Find the right shredder

FIND THE RIGHT SHREDDER

Our plastic shredder

Input materials

INPUT MATERIALS

Which types of plastic can be shredded?

Post-consumer plastic waste

Our reputation is built on the deployment of exceptionally powerful and exceedingly reliable shredding systems for our clientele. We are recognized for our commitment to providing cutting-edge solutions that excel in handling the intricacies of post-consumer waste, ensuring efficient and dependable processing to meet the demands of our customers.

Plastic containers

Our plastic shredders rise to this challenge with specialized push-in and push-down systems, ensuring the reliable and efficient shredding of various hollow bodies. Whether it’s drums, tanks, canisters, bottles, pipes, or IBCs, our shredders are adept at processing these materials with precision, addressing the unique demands posed by their size and structure.

Plastic fibres and bands

Efficiently shredding filaments, small bands, big bags, fleece materials, ropes, and textiles demands a precise cut. Our robust plastic shredders are meticulously crafted for this purpose, featuring a heavy-duty design that ensures smooth and efficient shredding of even these challenging materials.

Lumps

Our range of plastic shredders encompasses diverse cutting systems, drive capacities, and infeed dimensions, enabling us to precisely tailor the shredder to suit your clump materiala. Whether your material comprises PE, ABS, PP, PS, or PA, our shredders are engineered to process these materials with utmost efficiency and reliability.

Plastic film waste

Plastic film waste comes in many forms, from pre-sorted production waste to contaminated mixed commercial waste, and each form requires unique handling. Whether it’s the precision required to pre-sort waste or the efficiency required to blend commercial waste, our machinery configurations are engineered to meet the unique needs of each application.