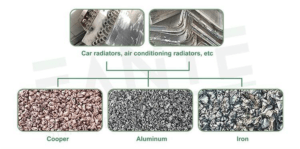

Radiator recycling is a critical process for recovering valuable metals such as copper and aluminum from end-of-life automotive radiators. With increasing environmental regulations and rising raw material costs, businesses are adopting advanced radiator recycling machine and establishing dedicated radiator recycling plant to maximize resource recovery and operational efficiency.

This article provides a detailed breakdown of the radiator recycling process, the essential machinery involved, and key considerations for selecting the right radiator recycling solution for your operation.

The Importance of Radiator Recycling

Automotive radiators consist of a combination of copper, aluminum, and steel. Improper disposal in landfills leads to environmental contamination and wasted resources. Professional radiator recycling offers significant advantages:

- Metal Recovery: Extracts high-purity copper and aluminum for reuse in manufacturing.

- Resource Conservation: Reduces reliance on energy-intensive mining of virgin metals.

- Cost Efficiency: Lowers production expenses for industries reliant on these metals.

- Sustainability Compliance: Supports eco-friendly waste management and circular economy initiatives.

These benefits make radiator recycling plants a strategic investment for scrap metal processors and automotive recyclers.

Step-by-Step Radiator Recycling Process

Efficient radiator recycling involves a systematic approach to ensure maximum material recovery and minimal waste.

1. Manual Pre-Sorting

Workers inspect and remove non-metallic components such as plastic housings, rubber fittings, and debris to prevent contamination during processing.

2. Mechanical Shredding

A specialized radiator recycling machine shreds the radiators into smaller fragments, increasing surface area for better separation. Industrial-grade shredders ensure consistent output for downstream processing.

3. Metal Separation

Advanced separation technologies, including:

- Air Classification: Separates lightweight aluminum from heavier copper.

- Magnetic Separation: Removes residual iron and steel components.

- Eddy Current Separation: Further refines non-ferrous metal purity.

This multi-stage separation achieves metal recovery rates of 98% or higher.

4. Material Collection and Packaging

The recovered metals are sorted, cleaned, and compacted for resale to smelters or metal manufacturers.

Key Factors in Selecting a Radiator Recycling Machine

Investing in the right radiator recycling machine is crucial for operational success. Consider these factors:

- Throughput Capacity: Machines should match your processing volume (e.g., 1,000 kg/h vs. 5,000 kg/h).

- Separation Accuracy: High-purity output increases resale value of recovered metals.

- Automation Level: Fully automated systems reduce labor costs and human error.

- Durability: Wear-resistant components minimize downtime and maintenance.

- Vendor Support: Reliable after-sales service ensures long-term productivity.

Premium radiator recycling plants integrate these features to handle diverse radiator types, including copper-aluminum hybrids and multi-layer designs.

Business Advantages of Radiator Recycling

Establishing a radiator recycling plant delivers measurable benefits:

- Revenue from Scrap Metals: Copper and aluminum have strong market demand.

- Regulatory Compliance: Meets environmental standards for waste processing.

- Sustainability Branding: Enhances corporate responsibility credentials.

- Operational Scalability: Modular systems allow for future expansion.

Final Recommendations

For automotive recyclers, scrap metal dealers, and sustainable manufacturers, radiator recycling presents a profitable and environmentally sound opportunity. Implementing an optimized radiator recycling machine improves efficiency, reduces waste, and ensures compliance with global sustainability trends.

To explore customized radiator recycling solution for your business, contact our team for a consultation.