A scrap metal recycling machine plays a vital role in modern recycling operations, helping reduce landfill waste, recover valuable materials, and promote sustainable manufacturing. Among the various machines used, the scrap metal shredder is the most powerful and versatile tool in dismantling and processing waste metals. But what kinds of scrap metal can it handle?

This article explores the capabilities of a metal shredder machine and the types of scrap metal it’s designed to process effectively.

1. Common Types of Scrap Metal Processed by a Metal Shredder Machine

A metal shredder machine is engineered to break down a wide variety of ferrous and non-ferrous metals. Here’s a breakdown of the most commonly processed materials:

a. Aluminum Scrap

-

Used beverage cans

-

Window frames

-

Automotive parts

-

Extrusion profiles

Aluminum is lightweight yet strong, making it a prime candidate for recycling. Shredders reduce its volume and prepare it for smelting.

b. Steel Scrap

-

Structural beams

-

Rebar

-

Car bodies

-

Steel drums and containers

High-strength scrap metal shredder systems are often equipped with hardened blades and wear-resistant components to handle dense steel waste.

c. Copper Scrap

-

Electrical wiring

-

Copper tubing

-

Bus bars

-

Motor components

Though softer than steel, copper requires precision shredding to preserve its value and facilitate downstream separation.

d. Stainless Steel

-

Industrial equipment

-

Kitchenware

-

Piping systems

Stainless steel’s resistance to corrosion and heat makes it valuable in recycling but challenging for some light-duty machines—requiring a heavy-duty scrap metal recycling machine.

e. Automotive Scrap

-

Engines

-

Radiators

-

Transmissions

-

Car bumpers and wheels

Automotive scrap combines many different metal types, making a powerful metal shredder machine essential for effective pre-processing.

2. Industrial Applications of Scrap Metal Shredders

a. Recycling Centers

Municipal and private recycling centers rely on scrap metal shredder units to handle daily tons of collected waste.

b. Manufacturing Facilities

Many factories generate significant metal scrap. A scrap metal recycling machine helps reduce waste volume and recycles internal production scrap.

c. Auto Dismantling Yards

A metal shredder machine is critical in auto recycling operations to process vehicles and recover reusable metals from frames, parts, and systems.

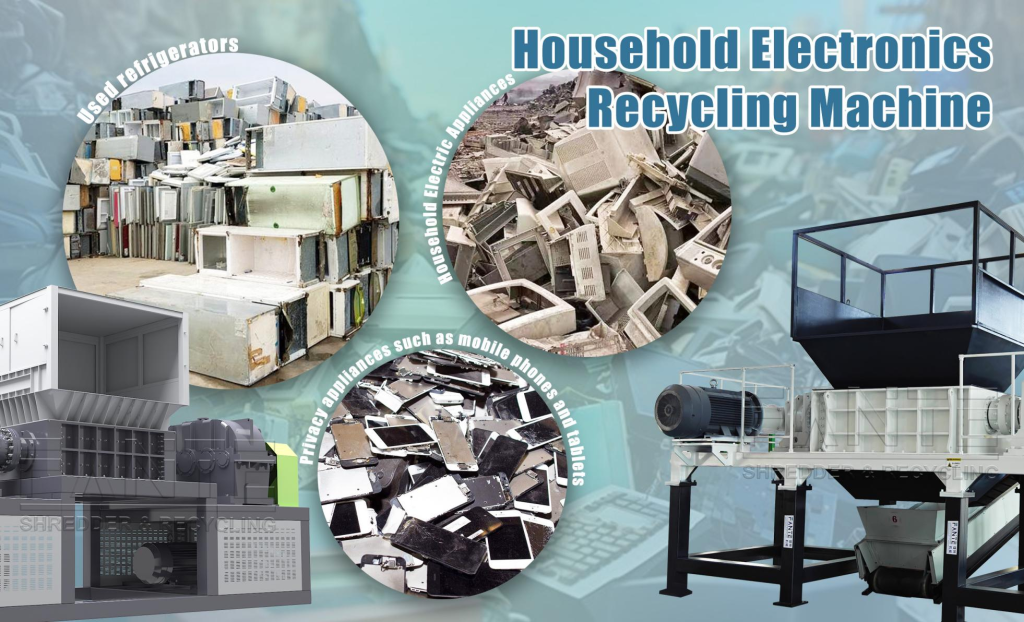

d. Electronic Waste (E-Waste) Processing

Shredders can also assist in disassembling and separating metallic components from electronic devices, making them ideal for e-waste recycling.

3. Choosing the Right Scrap Metal Shredder for Your Needs

When selecting a scrap metal shredder, consider:

| Criteria | Details |

|---|---|

| Material Type | Aluminum, steel, copper, stainless steel, mixed metals |

| Shredder Capacity | Small (300 kg/h) to large-scale (10+ tons/h) |

| Output Size Requirement | Adjustable depending on downstream processing needs |

| Machine Durability | Hardened steel blades, wear-resistant chamber materials |

| Energy Efficiency | Important for long-term operational cost control |

Conclusion

A metal shredder machine is capable of handling a diverse range of materials—from lightweight aluminum to heavy steel. Whether you’re operating a small recycling facility or a large industrial plant, investing in the right scrap metal recycling machine enhances operational efficiency and maximizes metal recovery.

By understanding what types of metals your shredder can process, you’ll make more informed decisions and significantly boost your recycling ROI.

Looking to upgrade your scrap metal processing line? Contact us for expert advice and tailored shredder solutions.